Factors Influencing on the Dimensions Accuracy in Laser Cutting

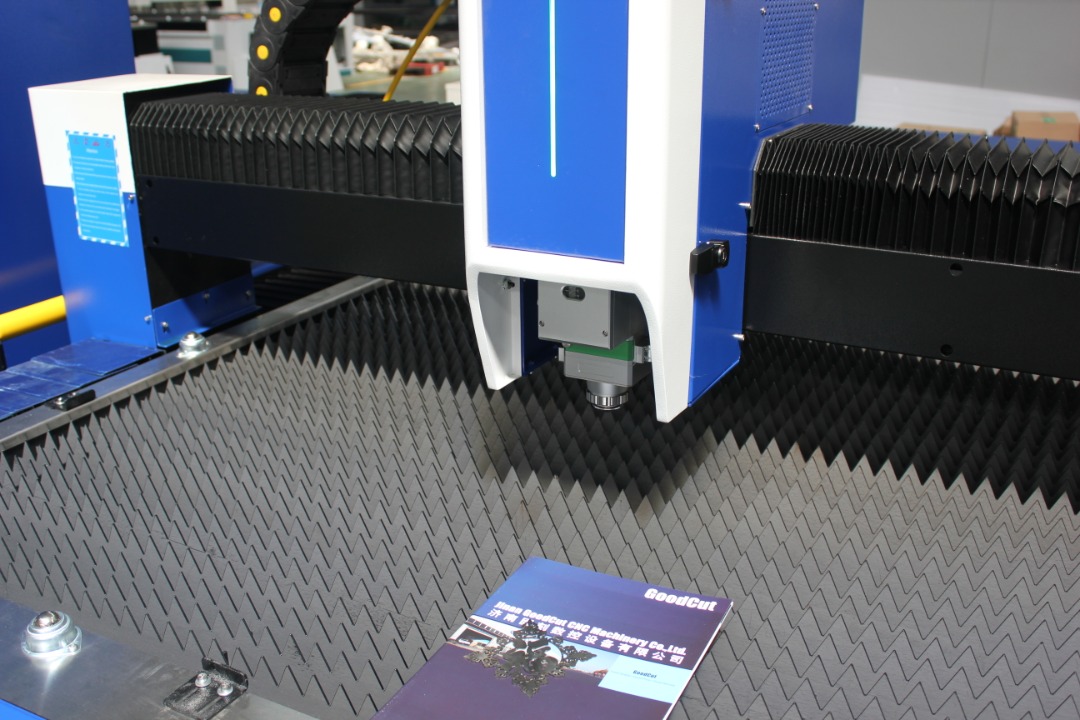

We confirm a laser cutting machine manufacturer is excellent, the cutting precision is the first standard. Therefore, how to confirm the cutting precision whether qualified will be from the following four factors considered

1. the size of the laser coagulation of the laser generator. If the spot is very small, the cutting accuracy is very high, and if the gap is very small after cutting. It shows that the precision of laser cutting machine is very high, and the quality is very high.

2. the accuracy of the working table. If the accuracy of the working table is very high, then the accuracy of the cutting will be improved. Therefore, the precision of the working table is also a very important factor to measure the accuracy of the laser generator.

3. laser beam condensed into a cone. When cutting, the laser beam is to taper down, when the thickness of the workpiece cutting is very large, cutting accuracy will be reduced, cut out the gap will be very large.

4. cutting the material is different, also will affect the precision of the laser cutting machine. In the same case, the cutting of stainless steel and aluminum will be very different accuracy, stainless steel cutting accuracy will be higher, and the section will be smooth.

How to focus the laser

The laser beam is focused through the focal lens. The focal lens acts like a magnifying glass and sunlight. For a 55mm lens, the laser beam passes through the lens and converges to the smallest point at about 55mm from the edge of the lens. The laser beam is concentrated to the smallest size at this "spot". Given that the lens is mounted in the focal tube, the question is how to put the material at the optimum location to engrave or cut.

First, think of what results are desired. Whenever we want to engrave, we want to have the laser beam focused to the smallest spot and that spot located at the top surface of the material. Having the smallest spot size will give us the best resolution. the best DPI (dots per inch). The laser machine should have come with a manual height measurement tool. Some machine come with a square piece or acrylic to match to a marker on the side of the focal tube. Other machines come with a feeler gauge that snuggly fits between the focal tube nozzle and the top surface of the material.

The normal adjustment method is to place the material on the worktable and then to move the worktable height such that the top surface of the material is at the focus spot of the laser beam. Use the measurement tool while moving the table to the proper height. Make sure not to move the table too far. You will not want to damage the table surface, material, or the focal assembly.

Most laser machines have a movable table height. If the table will not move or is already moved to the top, then the focal tube has some adjustment to move/slide up and down about 1.5 inches. First, loosen the focal tube nut (or screw). Second, move the focal tube to the desired height above the material surface. Last, tighten the focal tube nut (or screw).

You may be concerned that you are using the provided tool to place the focus at the prescribed distance, but the focus just doesn't seem right. Please remember that the Chinese optics are not the best. The optimum focal distance might be slightly closer or farther away from the lens. Place a piece of flat scrap material (wood) under the focal assembly. Adjust the focus such that the material is slightly too close to the focal lens. Use the "laser" button to make a test spot on the wood. The spot size will be larger than desire for engraving. Move the table away from the lens just a small distance. Move the wood to a clean target location. Make another test spot using the "laser" button. The spot size should have gotten smaller. Continue moving the table and making test spots on the wood surface. When the spot starts getting bigger, then you have just passed the focal point. This is the easiest way to find the true focal distance of your lens.

Contact: Candy Guan, Max Yuan

Phone: 008613170811607, 008618396850306

E-mail: candyguan@goodcutcnc.com

Whatsapp:008613170811607, 008618396850306

Add: A2 Block, Sanqing Shiji Caifu center, High-tech district, Jinan City, Shandong Province, China

We chat